Advanced technology

for optical applications

What we do

ODL designs and manufactures a complete line of thin-film coatings for customized solutions for industrial and technical sectors.

These include dichroic filters and mirrors for the control of the electromagnetic spectrum in its ultraviolet, visible, and infrared components, as well as the development of metal deposition processes in the design and decorative fields.

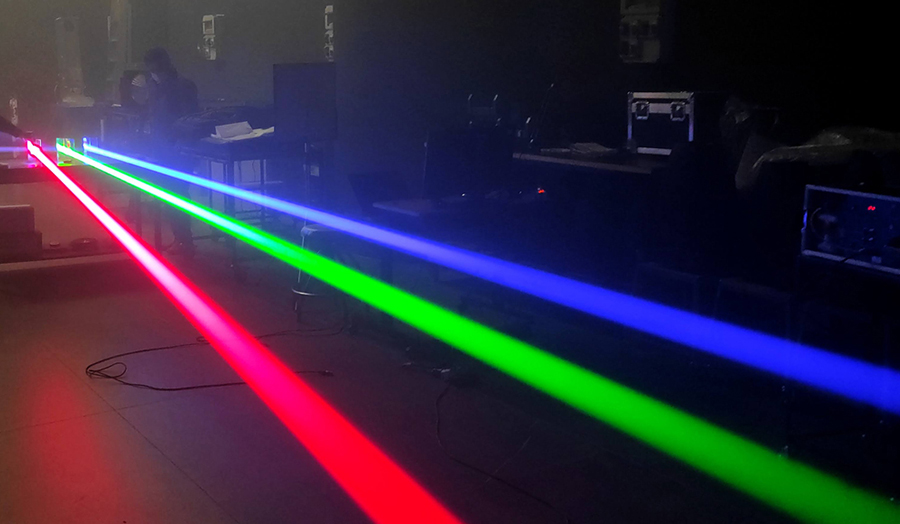

Products

ODL provides both functional and decorative coatings:

- Aesthetic finishes for design and fashion accessories and components

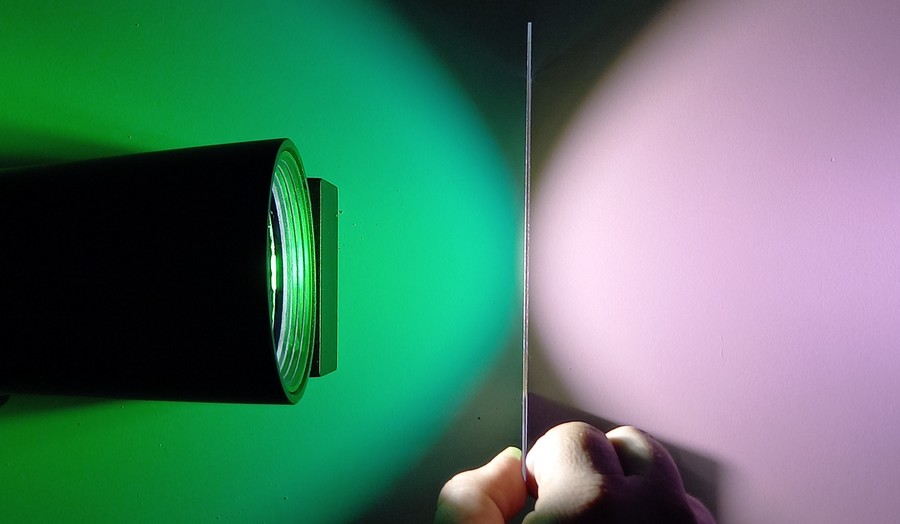

- Cold Light Mirror Dichroic Reflectors (CLM)

- High Reflectivity Mirrors (HR)

- Dichroic Color Filters

- Filters to separate or combine wavelengths

- Heat Reflection Filters (IR Block; infrared NIR and SWIR)

- Color Temperature Correction Filters (TC)

- Indium Tin Oxide (ITO)

- UV Block Filters

- Beamsplitter Coating (BS)

- Anti-Reflection Coating (AR)

- Led Filters

- Gobos

- Custom products

Services

- R&D Center and Sampling Service

- Optical Coatings

- Optical Assembly

- Dicing

- Glass Polishing & Lapping

- Glass Grinding

- Cutting

- Laser Etching

Substrates

We can treat different materials:

- Glass

- Metal

- Polymers

- Ceramic

- Others on request

Shapes and Sizes

We can treat different shapes and sizes:

- 3d objects and components

- Flat or curved surfaces

- Rigid or flexible surfaces

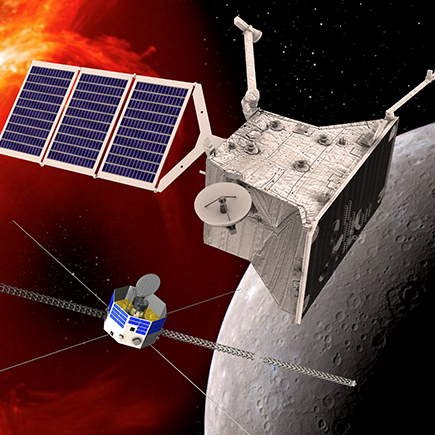

Our fields of application

Technology

What’s PVD?

Acronym of Physical Vapor Deposition, PVD is the under vacuum technology of applying a thin film of material, typically metals, metal oxides and other compounds of a few microns of thickness, on to a substrate material or object.

The aim is to form a thin, bonded surface layer that greatly improves appearance and properties of the substrate, for both Decorative and Functional purposes.

ODL’s coatings are deposited through PVD processes by Evaporation technology from a melting source, and by Sputtering technology, through atoms injection from a solid source bombarded with ionized gases.

Advantages of PVD Coatings

- High durability and abrasion resistance

- No corrosion, oxidation, or blackening

- Chemical inertness to aggressive environments

- Inalterability to UV light

- Many finishes and colors

- Wide innovation possibilities

- High degree of repeatability

- Eco-friendly

Sustainability

Committed to the environment

PVD is certified for meeting environmental regulations and being the sustainable and cost-effective alternative to polluting paints and galvanic finishes.

Not only is PVD more sustainable from an environmental point of view, but also from an innovation and competitiveness perspective. PVD is the preferred choice when it comes to quality, durability, and sustainability.

Compliant with REACH and RoHS regulations

Compliant with REACH and RoHS regulations

Chemical-free and waste-water free production

Chemical-free and waste-water free production

No harmful emissions

No harmful emissions

ODL Company

The history of ODL (Optical Deposition Laboratory) begins in 1987 with the foundation of a research laboratory by two physicists in Bergamo (Italy) having years of experience in the thin film coating technology for optical applications.

Today, ODL has grown into an international high-tech enterprise, with advanced equipment and 40 high skilled professionals working in a dynamic and customer-oriented organization, with offices in Italy and China.

In 2006, the company opened a branch in Guangzhou (China) devoted to products cutting and shaping finishing for Asian customers who require Made in Italy products that meet the specific requirements of their local markets.

The production capability is over 900 sqm of glass coating per month.

Through its projects ODL operates in 5 continents.

Contact

ODL S.r.l.

Via G. Terzi di S. Agata, 17

24030 Brembate di Sopra

Bergamo - Italy

info@odlcoating.com

+39 035 332213

ODL (Guangzhou) Optical Coatings Ltd.

8/F, South Part, No. 231 Kaifa Avenue, No. 52 Jinxiu Road

Guangzhou Economic & Technological Development Zone, Huangpu District

Guangzhou 510730, P.R.China

sales@cn.odlcoating.com

+86 20 82218376